As powder formulations for functional beverages become increasingly complex, more companies are turning to powder blending services for support. Behind every consistent powder blend is controlled mechanical movement, precise particle movement management, and tight process controls. Through proper blending, the uniform distribution of ingredients ensures that every batch of finished product meets established composition and performance requirements.

Why Blender Type Matters for Powder Blending Services

The type of blender and blending process determines how well the powder formulation maintains uniformity, stability, functionality, dissolution rate, and sensory attributes, ensuring the final product can meet quality requirements and label claims. Because some ingredients, such as artificial sweeteners, are added in micro amounts compared to other ingredients, uniform blending is essential.

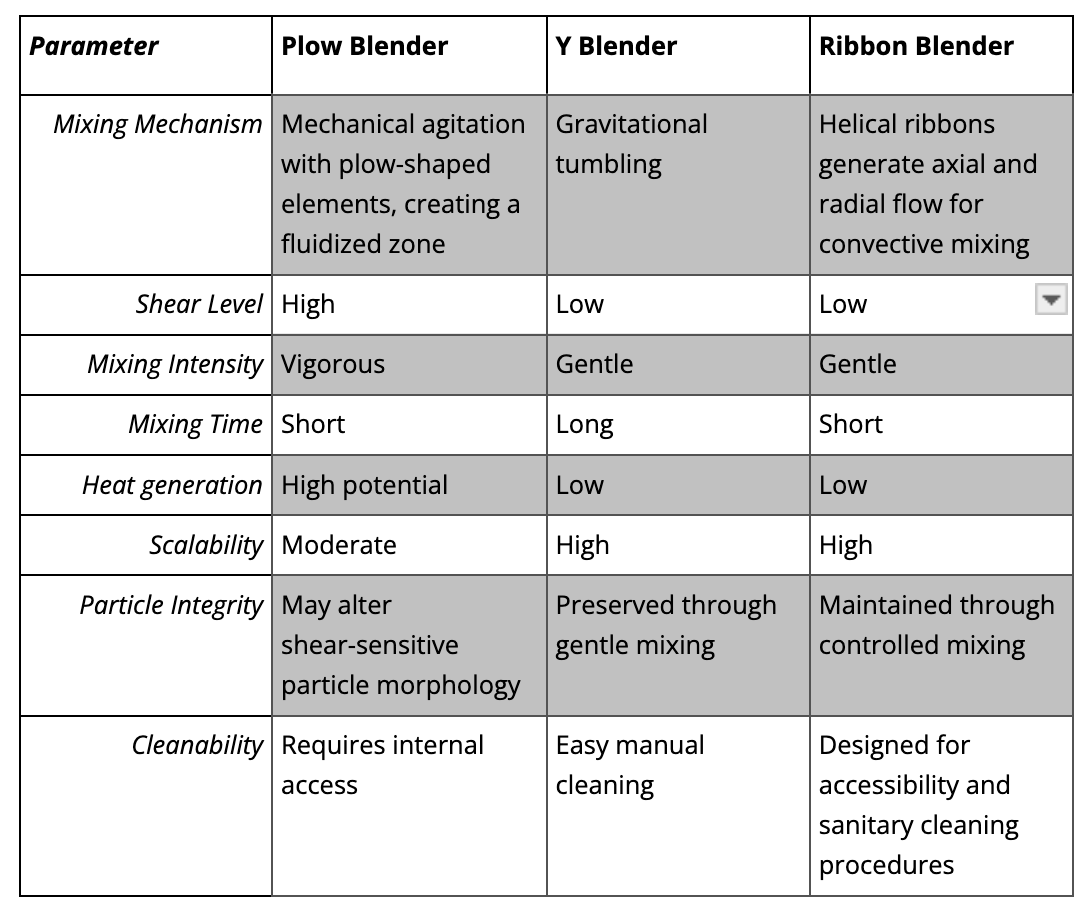

The flow patterns, shear forces, and mixing mechanisms vary across different blender types. Working with a trusted partner for your powder blending services will ensure the blender is suited to the powder formulation, preventing overworking or damaging the powders.

Three types of blenders are commonly used in powder formulation processing: the plow blender, the Y blender, and the ribbon blender.

How Plow Blenders Work

Plow blenders use high-speed plow-shaped elements mounted on a horizontal shaft within a cylindrical chamber to generate an intense mechanical mixing action. The plows lift material from the bottom of the vessel and propel it at high velocity into the free space above, creating a fluidized mixing zone. The vigorous motion of a plow blender supports efficient mixing in formulations that require fast cycle times. This harsh mixing action can break down fragile powder particles, cause smearing on blender walls, and lead to detaching flakes, making plow blenders most suitable for applications that can withstand the rigorous handling.

How a Y Blender Works

The Y blender, also called the V blender or twin shell blender, consists of two cylindrical sections joined at an angle to form a “V” or “Y” shape that rotates around a central axis. The blending action relies on gravitational movement as opposed to mechanical agitation. As the vessel turns, material repeatedly tumbles and cascades, dividing and recombing, generating diffusion-based mixing with minimal shear. This design is suitable for free-flowing powders and materials that must retain their original particle size or morphology. Mixing is less thorough, and mixing times are much longer than in mechanically agitated systems, but the process environment remains gentle and controlled.

How a Ribbon Blender Works

Ribbon blenders employ a horizontal trough fitted with inner and outer helical ribbons pitched in opposite directions, mounted on a central shaft. The ribbons rotate in opposing directions, ensuring lateral and radial blending. This countercurrent motion generates consistent circulation throughout the batch and supports a uniform blend. The design provides measurable control over shear and residence time, protecting the integrity of functional ingredients like probiotics, vitamins, and botanicals.

Because the mixing action is continuous and well-distributed, ribbon blenders can achieve a high level of homogeneity within predictable time intervals, even with varying particle sizes. They are also adaptable to a wide range of powder characteristics, making them suitable for formulations where consistent composition, controlled dissolution, and stable physical properties are required. Ribbon blending is highly scalable, making it ideal for pilot- to commercial-sized batches.

Comparison of Common Powder Blender Designs

Powder Blending Services From Tipton Mills

At Tipton Mills Foods, powder blending services is just one element of our complete solution for functional powdered beverage manufacturing. However, it is a critical step in achieving the quality brands have come to expect.

We have chosen to use ribbon blenders because they align with the physical characteristics and process requirements of the powdered functional beverages we produce. Many of these formulations include active ingredients, flavors, and carriers with differing particle sizes, densities, and flow behaviors. The ribbon blender’s dual helical agitator system supports both axial and radial movement, promoting uniform distribution across the entire batch. This flow pattern is particularly effective for formulations where even dispersion is essential for performance and product stability.

The low shear environment of our ribbon blenders maintains the integrity of sensitive components, such as vitamins, probiotics, and proteins, while still achieving measurable homogeneity. The short processing time (typically 5-10 minutes) and predictable energy input allows blending to occur without heat buildup or degradation of compounds, which is important in functional powders where sensory and nutritional attributes must remain consistent.

Trust Built on Process Integrity

We have established brand trust in our powder beverage manufacturing results through our extensive knowledge, consistency, verification, and adherence to defined quality systems. Each production step, from ingredient preparation to packaging, is carried out under documented standard operating procedures. Equipment calibration, environmental monitoring, and lot-level traceability ensure that results can be reproduced and verified over time.

Batches are routinely evaluated for quality, including particle size distribution, moisture content, bulk density, and organoleptic testing to confirm alignment with our client’s formulation specifications. This level of process control allows brand owners to rely on the repeatability of each blend, knowing that the same inputs will yield the same performance. Through disciplined process management and data transparency, we foster confidence in both the blending method and the resulting product quality.

Make Tipton Mills Foods your trusted partner for functional powdered beverage solutions. Contact us to speak with a product specialist today.