Private label nutraceuticals have gained traction in the functional powdered drink market, driven by consumer demand for convenient beverages containing concentrated nutrients. For retailers, powdered nutraceutical beverages provide an efficient way to deliver functional ingredients while maintaining control over flavor, ease of use, and shelf life. Tipton Mills Foods guides brands through each step of the process, bringing nutraceutical powders from an idea to retail shelves.

From Concept Through Formulation

Retailers with a successful private label brand understand the critical importance of being true to their brand’s positioning and target consumer. The same is true for private-label nutraceuticals; however, the desired functional benefit must also be considered. For a powdered drink format, this means defining the active ingredients (e.g., vitamins, minerals, adaptogens, fiber), as well as the taste profile, solubility, texture, and packaging format.

When retailers come to us to formulate a new private label nutraceutical or solve a formulation issue, we employ a proven process designed to promote transparency and collaboration from initial discovery through partnership. The first step is consultation and discovery, where we learn about the brand’s needs and goals and determine the technical feasibility.

The next step is formulation, trials, and qualification. Our research and development team collaborates with clients to create custom formulas that meet both performance and sensory expectations. Relying on more than 25 years of experience, the team focuses on ingredient compatibility and the physical characteristics that determine how powders mix and taste when reconstituted. Often, brands ask us to convert a ready-to-drink formulation to an equivalent powdered version. Our food scientists also develop new recipes based on the brand’s nutritional and functional requirements.

To ensure the product meets both the brand and consumer needs, agglomeration, blending, and filling trials may be conducted. As we proceed with the project, we develop a comprehensive plan covering formulation, sourcing, production scheduling, and quality control measures.

Supply Chain and Material Sourcing

Once a formula is defined, it’s essential to secure the right ingredients and packaging materials. In powdered-beverage development, issues such as ingredient variability, moisture sensitivity, and supplier reliability can have a significant downstream impact. For turnkey solutions, we manage ingredient and packaging procurement through established supplier relationships that support quality and availability. Our process includes supplier evaluation, specification management, and documentation that supports traceability and verification.

This means that raw materials are carefully reviewed before manufacturing begins. Packaging materials are also evaluated to ensure they preserve the powder’s integrity through storage and shipment.

Manufacturing Private Label Nutraceuticals

Producing powdered nutraceutical beverages requires precision and control. Each stage of manufacturing affects the performance and sensory profile of the finished drink. Key considerations for manufacturing include:

- Blending uniformity: Ensuring even distribution of ingredients so each serving meets label claims.

- Powder flow and solubility: Managing particle size and moisture to prevent clumping and support smooth mixing.

- Flavor masking: Adjusting taste and mouthfeel when functional ingredients have strong natural flavors.

- Agglomeration: Improving texture and solubility through specialized processing.

Whether turnkey or contract manufacturing, at Tipton Mills Foods, production is carried out in a facility equipped for high-speed dry blending and agglomeration, and all products are manufactured to Good Manufacturing Practice (cGMP) standards.

Packaging and Shelf Stability

Powdered nutraceutical beverages depend on proper packaging to maintain product quality. Barrier protection against moisture and oxygen extends shelf life and helps to preserve flavor and maintain nutrient activity.

Tipton Mills provides a range of packaging formats, from single-serve stick packs to multi-serve cans and pouches. Packaging selection is guided by the product’s intended use, the client’s needs, and the desired consumer experience. Proper primary packaging also helps maintain flow characteristics and ease of mixing after purchase.

Quality Assurance and In-House Testing

Quality control is critical to ensure uniformity across servings, reliable performance in terms of solubility and texture, and consistency from batch to batch. For brands producing private label nutraceuticals in powdered drink format, working with a partner that handles in-house testing and full process monitoring reduces product risk and supports stronger shelf performance.

At Tipton Mills Foods, we maintain a robust quality assurance program and dedicated in-house testing capabilities. We operate under fully documented HACCP-based food safety plans, and our facility uses metal detection, X-ray screening, and rigorous allergen management to safeguard product integrity.

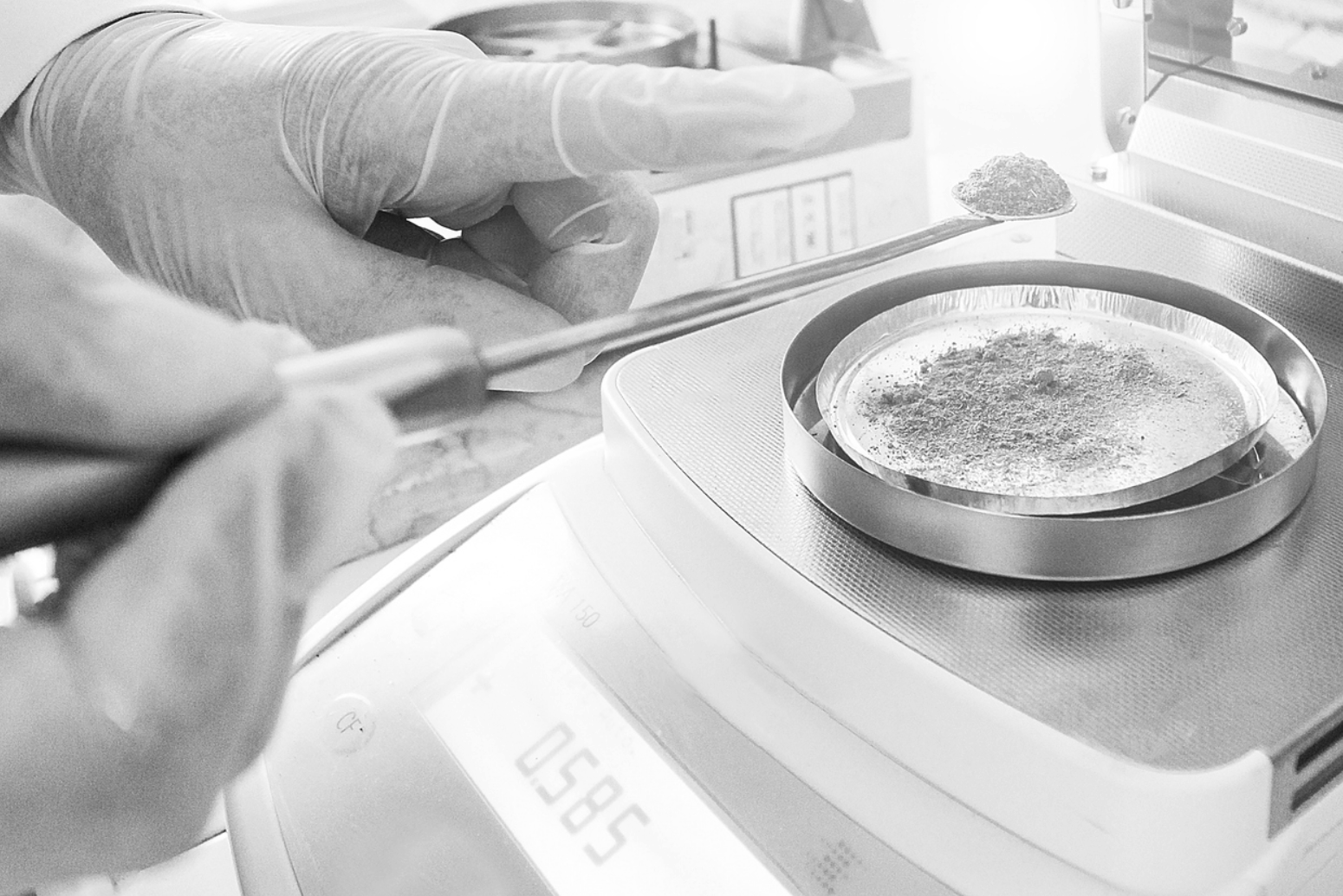

Proactive controls, operator training, and routine verification of cleaning and maintenance procedures are integrated components of our quality system. Additionally, we conduct a range of internal tests (e.g., particle size distribution, moisture analysis, bulk density and flow, viscosity, pH, organoleptic assessments) to verify both the raw material attributes and the finished product’s performance.

Importance of Process for Private Label Nutraceuticals

Process control determines the consistency, quality, and performance of powdered nutraceutical beverages. A structured manufacturing approach helps prevent quality variations and maintain consumer trust. When brands work with a partner that outlines each stage from formulation through packaging, they gain predictability and confidence in their product line.

By working with us, brands can be assured that their products are developed and manufactured using an established process that will deliver the flavor, stability, and reliability consumers expect.

Contact us for a consultation.